At Gateway Farms everyone is acutely aware of the community in which the company operates, and community service forms one of the pillars of the company’s mission. Any vacancies are filled, unless completely impossible, by people from the local community and all promotions are first considered from within.

“I am very proud of the fact that in 25 years I have never retrenched a single employee,” says CEO Bill Beghin, who started the company in 1991, a few years after graduating from the then Natal University (now UKZN) with a business degree.

When his founding partner died unexpectedly in 1997, Bill took over the reins and has been running Gateway Farms ever since.

First started as a fruit packing company for the citrus, avacado and tomato growers in the area ,Gateway has slowly transformed into a company contract packing fresh fruit for South Africa’s major retailers and beverages for well-known brands.

In keeping with a corporate culture that demands ever more socially responsible methods of production, Bill has introduced two eco-friendly operations which together have produced substantial benefits both for the planet and for the bottom line.

One is a water recycling system that returns used water - which used to go down the drain - to the boiler for use in providing the heat for the hot-fill lines. This has cut the company’s water consumption in half.

And the second is a quite extraordinary story of how to use low tech

solutions to solve quite high tech problems (see below).

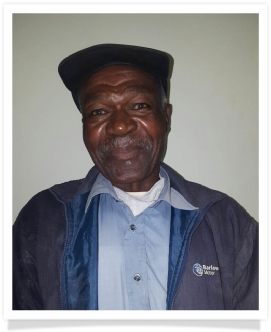

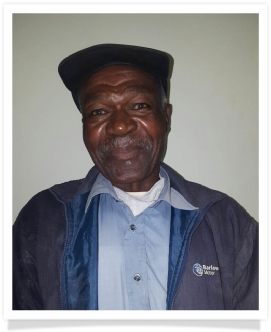

Local entrepreneur and Gateway

partner for a triple win solution

Always on the lookout for more socially responsible ways of doing business, Gateway Farms’ relationship with local businessman Mr Solomon Dukuza is a good example of how innovative attitudes can produce win-win situations.

Mr Dukuza contracts with local timber growers to thin out their forests. This means he has a constant supply of timber that is the ideal size for the boiler. Gateway purchases this timber from him, giving him a regular source of extra income to employ his staff, and the logs are used to fuel the outside boiler needed for any hot-fill work the company may have on hand.

Not only does this prove an effective way of destroying under-sized and unwanted timber but it also lessens the company’s dependency on Eskom’s national grid and very effectively reduces the cost of heating liquids prior to a hot-fill production run.

Gateway benefits, Mr Dukuza benefits and the nation benefits – it’s actually a “win-win-win” solution!

The 1 ton boiler (above) is fuelled entirely by the logs (below) harvested in a forest gleaning programme conducted by a local community member, thereby saving Gateway extra electricity bills and reducing the carbon footprint for the operation by using a sustainable resource to fuel the boiler.